QUALITY OVERVIEW

GREENHOUSES & COLD FRAMES

Perfection is in the detail

We have developed our greenhouses especially for the discerning hobby gardener. Quality and functionality are at a professional level. The variety of models leaves nothing to be desired: There is the right greenhouse for every garden, and with our cold frames you can also consistently focus on growth. You will be impressed by the high product quality, user-friendly, simple installation and long-lasting functional reliability.

Continuous aluminum profiles are joined together using patented plug-in screw connections to form a stable basic structure. A special glazing technique gives the highly break-resistant ISO twin-wall sheets made of polycarbonate (6, 10 and 16 mm thick) with UV protection a secure hold.

Many useful details are included as standard: split hinged doors with lockable door handle, large roof windows with automatic window opener, large rear wall windows with manual openers, rain gutters on both sides, from 10 mm glazing thickness with downpipe – perfect.

- Large-format continuous channel profile with drain.

- Wide skylight with automatic window regulator: An oil-wax mixture in the cylinder expands with heat and pushes the piston out. The window opens automatically. When the temperature drops, the mixture contracts again and the window closes.

- Stable, continuous ridge profile.

- Large rear wall window.

- Sturdy basic construction, secure plug-and-screw connection technology.

- Lockable door handle (except for Rhodo model)

- Continuous floor profiles – with foundation frame at an extra charge: Simply buried in the ground, it is connected to the greenhouse by a force-fit connection. Its special shape anchors it storm-proof in the ground. If there is a solid base to screw the greenhouse onto, you do not need a foundation frame.

- Safe, sophisticated glazing technology without clips or plastic strips.

- High standing or side wall (1.40 m to 2.00 m depending on model).

- High incidence of light thanks to a wide glazing grid and optimum roof pitch.

- Particularly smooth-running door hinge

CARPORT SYSTEMS

Well thought out as standard

Where people want to protect what is dear to them, or where they want to create a place in the sun, it is good when the functional and the beautiful harmonize perfectly. This is exactly what guided us in the development of our carport systems. Aesthetically pleasing and delicate in design, they are extremely sturdy and have long-lasting functional reliability.

The statically tested constructions made of high-quality aluminum profiles and unbreakable ISO twin-wall polycarbonate sheets fit easily into any home environment and become eye-catchers in their own right.

Here too, our patented plug-and-screw connection makes installation easy for the DIY hobbyist. Secure special glazing and UV protection are standard, rain gutter and downpipe are part of the extensive standard equipment.

- All screws made of stainless steel

- Safe and sophisticated glazing technology, without clips or plastic strips.

- Generous entrance width of at least 2.85 meters*.

Flexible clearance height of at least 2 meters*.

Optimum overall length of at least 5.31 meters*.

*Other dimensions available on request and at an extra charge. - Secure fastening system for anchoring to the floor.

- Large-format, continuous gutter profiles including downpipe.

- At least 125 kg/m2 roof load thanks to stable basic construction and secure plug-and-screw connection technology.

- Highly break-resistant ISO twin-wall sheets made of polycarbonate, 8 mm thick (Elbe), including “longlife” UV protection.

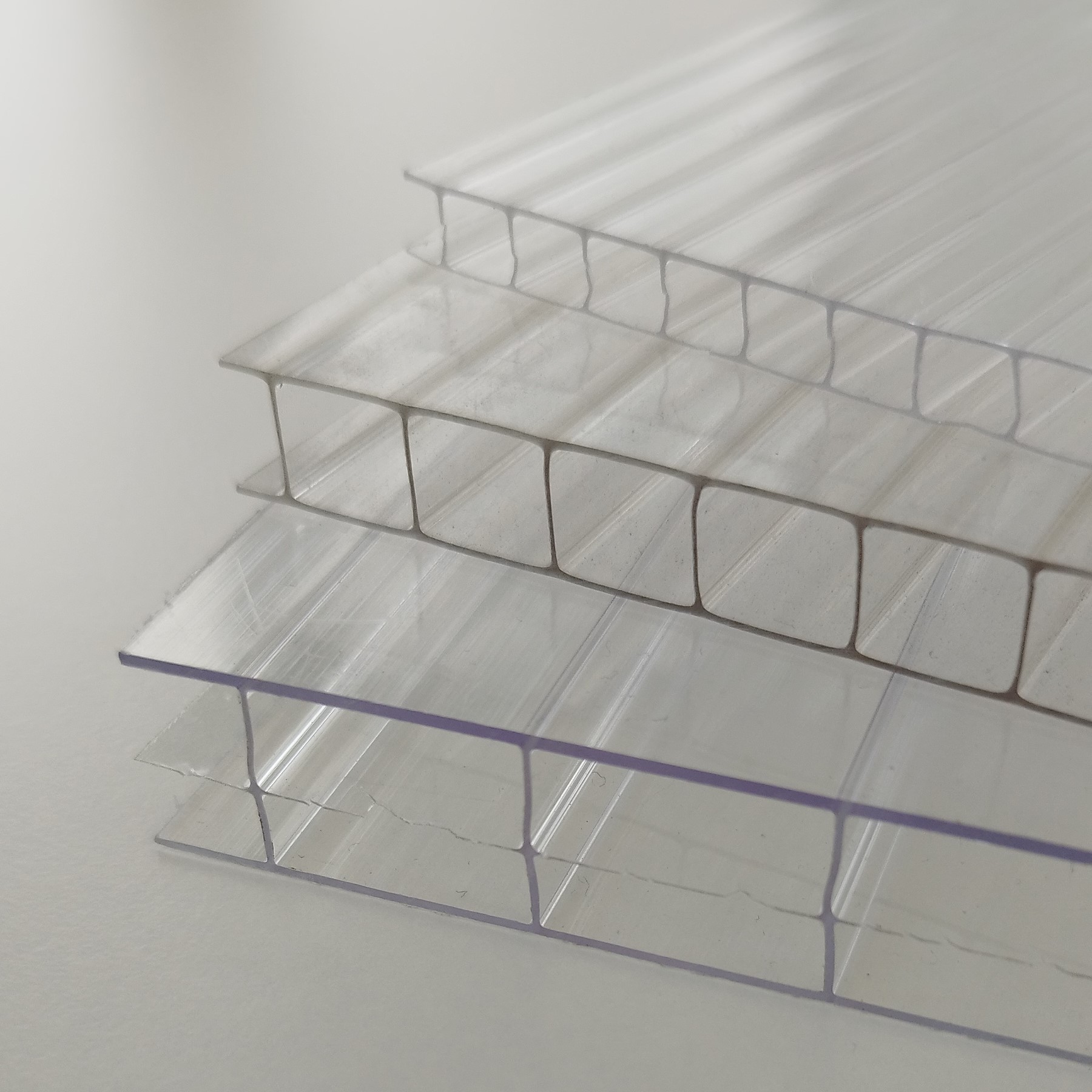

ISO-CAVITY PANELS (HKP)

How do the HKP of KGT models differ from other greenhouse manufacturers?

In principle, a 10 mm thick HKP should also be 10 mm thick for all greenhouse manufacturers. The decisive difference with HKP is the specific weight.

Stable HKP have at least the following weight:

- 6 mm = 1.3 kg/m²

- 10 mm = 1.7 kg/m²

- 16 mm = 2.8 kg/m²

However, manufacturers of HKP can save 20-30% of this weight during production. This allows the greenhouse manufacturer to save a lot of money without this being immediately apparent.

However, the specific weight has a massive influence on stability and resistance, e.g. to hail. Such “tricks” are often used with inexpensive greenhouses. The customer ends up having problems with defective HKP.

UV protection is just as important as the specific weight of the HKP. If no or poor UV protection is used, the HKP will become brittle and porous within a short time. As a result, the HKP are exposed to the weather without protection and are destroyed by even the smallest external influences.

Conclusion: Why you can rely on KGT as a greenhouse manufacturer!

KGT only uses high-quality HKP. We regard the specific weights mentioned as minimum standards and consider them to be lower limits.

Compliance with these values is monitored particularly closely by means of clear specifications and close-meshed spot checks. We rely specifically on high-quality UV protection, which is usually even applied on both sides.